Our areas of research

We stand for scientifically sound and practical research into polymer materials. We are involved every step of the way, from material development to processing and application-oriented testing. Sustainability is an integral part of all our research fields. Get an overview of our focus areas.

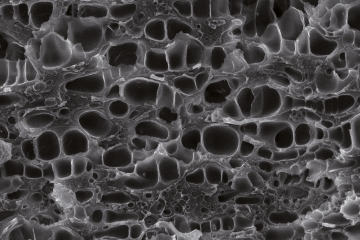

Polymer foams have unique properties thanks to their cellular structure. Their low weight and mechanical damping, coupled with excellent thermal and acoustic insulation, make foams attractive for many areas of application. These include applications in thermal insulation, packaging, footwear technology, structural lightweight construction, and many more.

We research the targeted adjustment of the structure and properties of polymer foams. To this end, we modify polymers, use existing manufacturing processes, develop new processes, and investigate the resulting properties in detail.

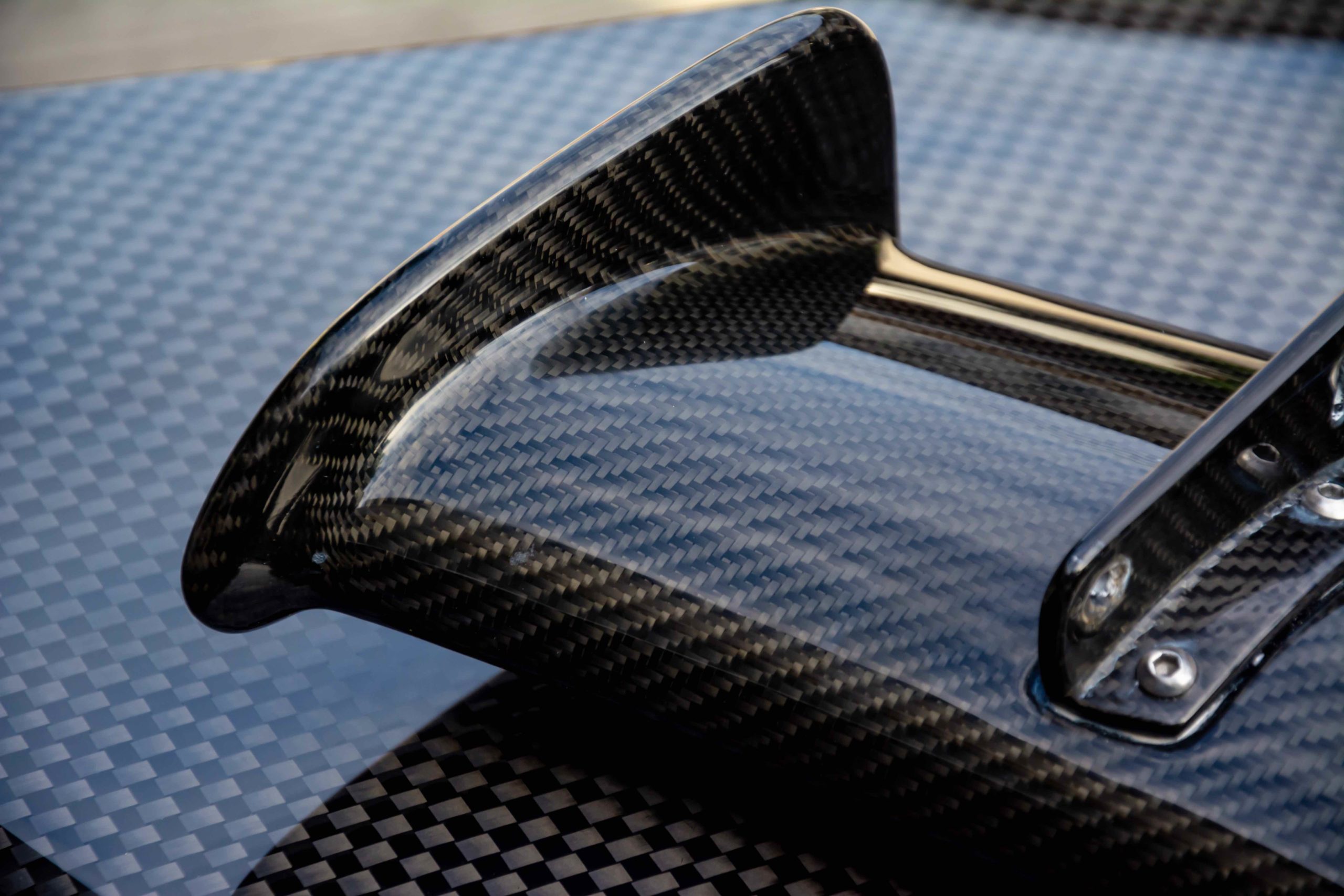

Fibre-reinforced composites combine low weight with excellent mechanical properties, and are therefore the material of choice for applications where lightweight construction concepts are required. The range of applications for fibre-reinforced plastics has expanded rapidly in recent years. Moreover, the fibre composite industry still holds great potential for growth looking forward.

We conduct research on fibre-reinforced composites and manufacturing technologies. Special attention is paid to the targeted modification of the matrix, for example to enhance the toughness, processability or flame-retardant properties of the fibre composite. We now also apply our knowledge of the targeted adaptation of resin systems in other areas of application such as medical technology.

Polymer materials can be optimised for processing and application through additives and other polymers. As a result, they can be made to meet the most demanding requirements and enable entirely new areas of application. However, they also require an in-depth understanding of the interplay between structure, processing, and properties, as they are typically multi-phase materials.

We research the targeted adjustment of the properties of thermoplastic materials. These functional thermoplastics are characterised by unique thermal, electrical, optical, mechanical, or processing properties. The use of such materials in additive manufacturing and other integrative manufacturing processes is particularly important to us.

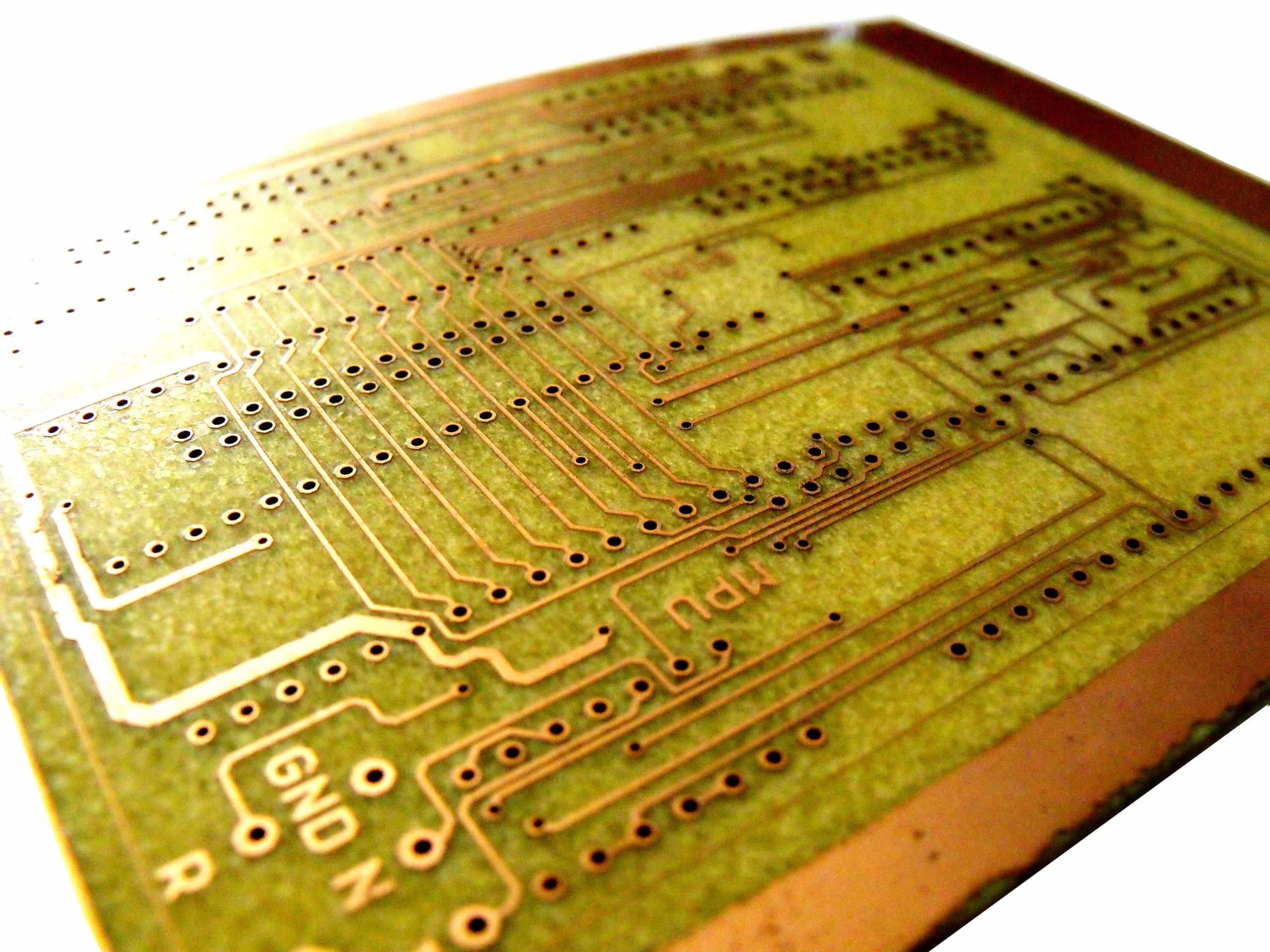

The future of the plastics industry is networked, and this applies equally to polymer research. Networked means both processes and data. The intelligent combination of different technologies, especially with new processing methods such as additive manufacturing, opens up new possibilities in product design. At the same time, the consistent use of information along the entire development and production chain is necessary.

We deal with the three key topics – digitalisation, integrative, and additive production – in order to advance the research and development of polymer materials. Equally important for us is the skilful interlinking of these priorities.

Sustainability and environmental protection are omnipresent terms in public discourse in connection with plastics these days. Society is calling for sustainable concepts and improved ecological footprints. Yet at the same time, it is interested in keeping the undeniable benefits of polymers in their many areas of application

We are therefore conducting research in three important areas to investigate and improve the sustainability of polymer materials. To begin with, we are investigating the impact of existing plastic products on the environment, for example in the form of microplastics. In order to improve sustainability in the long term, we are developing polymer solutions derived from biobased and biodegradable starting materials in our various research areas. And finally, we deal with the recycling of polymers.