Thermal analysis

Analysing the thermal properties of polymeric materials

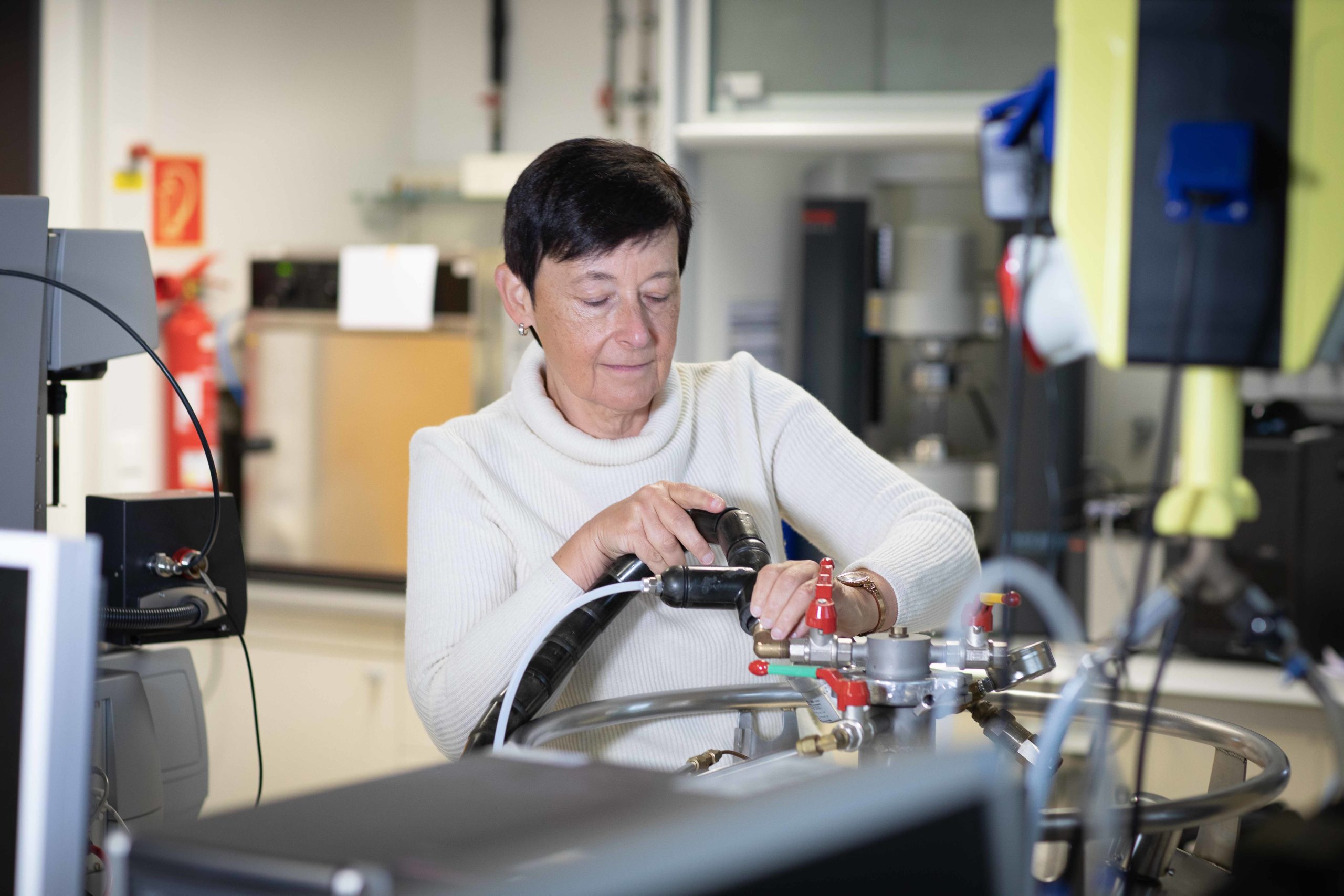

In thermal analysis, we combine the latest equipment with extensive experience. Depending on the task, we can use static as well as dynamic, highly-sensitive analysis methods. The wide range of methods enables professional support in the field of scientific and application-oriented research, product development, process and production control, as well as failure and damage analysis.

Contact: Dipl.-Chem.-Ing. Ute Kuhn

Phone: +49 921 55 74 75

E-mail: ute.kuhn@uni-bayreuth.de

The MCR 702 with MultiDrive technology with two independent air-bearing motors enables the following modes of measurement:

- DMA in intensiv, bending, and compression with lower, air-bearing linear motor

- DMA in torsion with upper, air-bearing rotary motor

- Shear rheology with upper air-bearing rotary motor

- Combination of linear drive and rotation motor in one test

- SMT – Mode (“Separate Motor Transducer” )

- EC – Mode: Operation with only one motor

Linear actuator for DMA in tension, bending, and compression

Force [N] 0.0005 – 40

Path amplitude oscillation [µm] +/- 0.01 – 4500

Temperature range [°C] -130 – 600 (convection oven)

Heating rate [K/min] 35

Cooling rate [K/min] 30

Rotary operation for DMA in torsion and rheology

Maximum angular frequency ω [rad/s] 628

Angular velocity [rad/s] 10-9 – 314

Maximum torque [mNm] 230

Min. torque rotation [nNm] 1

Min. torque oscillation [nNm] 0.5

Torque resolution [nNm] 0.1

Normal force range [N] 0.005 – 50

Normal force resolution [mN] 0.5

Temperature range [°C] -130 – 450 (convection oven)

Features

Plate-plate (PP25), solid-state fixture (SRF5), cantilever (CTL35), compression (PP25), three-point bending (TPB10/TPB20/TPB40)

Software

RheoCompass

Location: University of Bayreuth

Maximum frequency [Hz] 100

Torque [mNm] 0.2 – 200

Maximum force [N] 150

Angle range [mrad] 0.05 – 500

Temperature range [°C] –150 … 600

Number of units 2

Features

Solid state terminals (rectangular geometry)

Measuring mode

Torsion

Software

TA Orchestrator

Location: University of Bayreuth

The Eplexor 500N combines dynamic mechanical thermal analysis with dynamic material testing

The system works with two independent drives for applying the static and dynamic load.

Electrodynamic oscillator system [N] 500

Dynamic force transducer [N] 150 and 500

Static strain [mm] up to 35

Dynamic strain [mm] +/- 1.5 and +/- 6

Temperature range [°C] -150 …. 500

Sample collector

Variable for compression, tension, bending

Testing

Ageing and immersion test for 3-point bending

Software

Evaluation frequency sweep, temperature sweep, time sweep, etc.

Software module

- Determination of numerical master curves (statements on material behaviour)

- Hysteresis analysis

Property of Neue Materialien Bayreuth GmbH

Location: University of Bayreuth

Temperature range [°C] -180 – 550 (+/- 0.1 )

Signal time constant [s] < 1.5

Measuring range [mW] +/- 500 (+/- 0.04µW)

Cooling rate (RCS) [°C/min] 100 (550 °C to 300 °C), 20 (550 °C to -20 °C), 2 (550 °C to -90 °C)

Cooling rate (LNCS) [°C/min] 100 (550 °C to 200 °C), 20 (550 °C to -100 °C), 2 (550 °C to -180 °C)

Purge gas

Nitrogen, Helium

Features

Sample changer for 50 samples

Software

Advantage Software

Location: University of Bayreuth

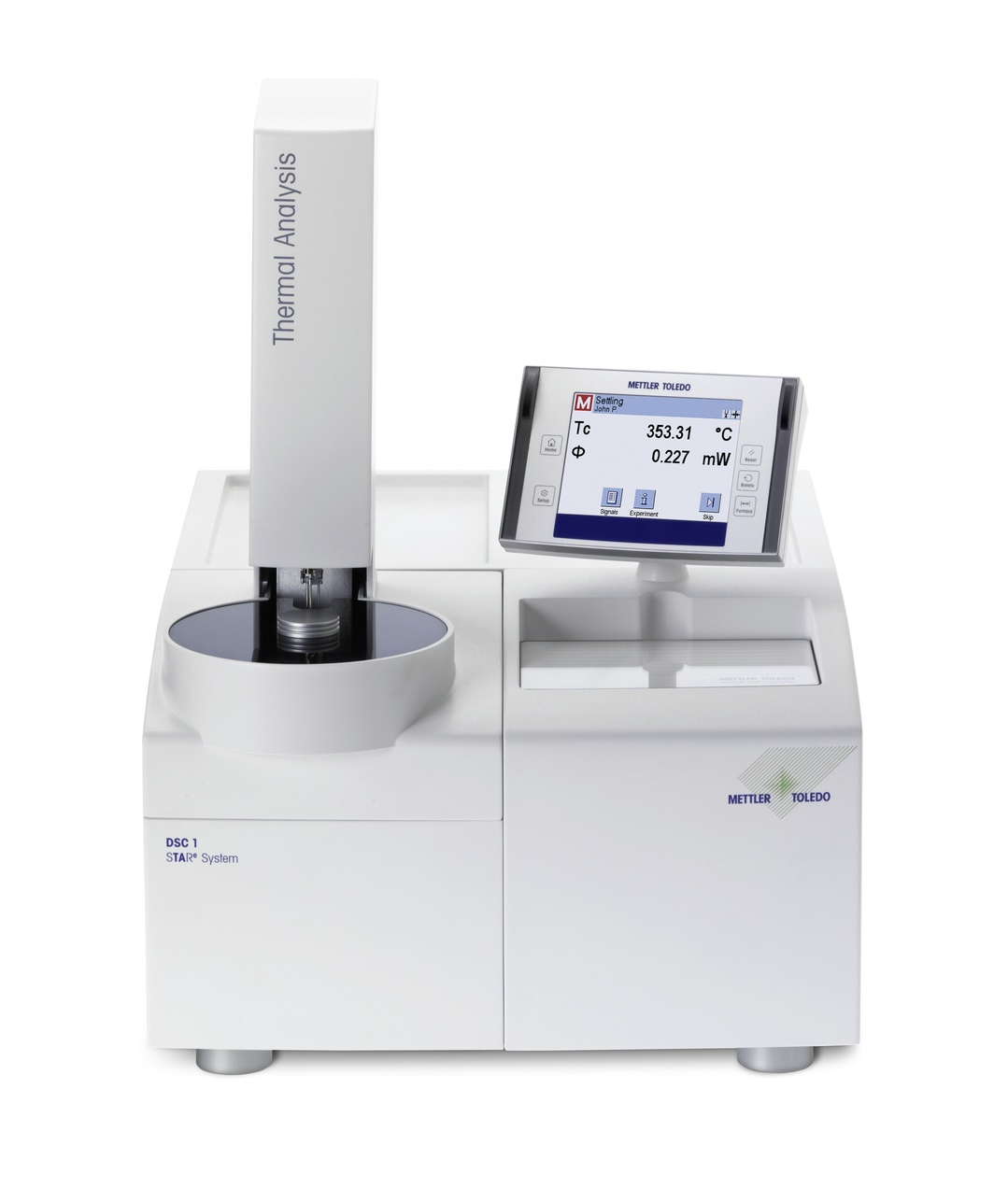

Temperature range [°C] -80 – 700

Signal time constant [s] < 1.7

Measuring range [mW] +/- 350 (+/- 0.04µW)

Heating rate [°C/min] 0.02 – 300

Cooling rate [°C/min] 0.02 – 50

Purge gas

Nitrogen, oxygen, air

Features

SDTA sensor: ceramic sensor FRS5, sample changer for 34 samples

Software

STARe

Location: University of Bayreuth

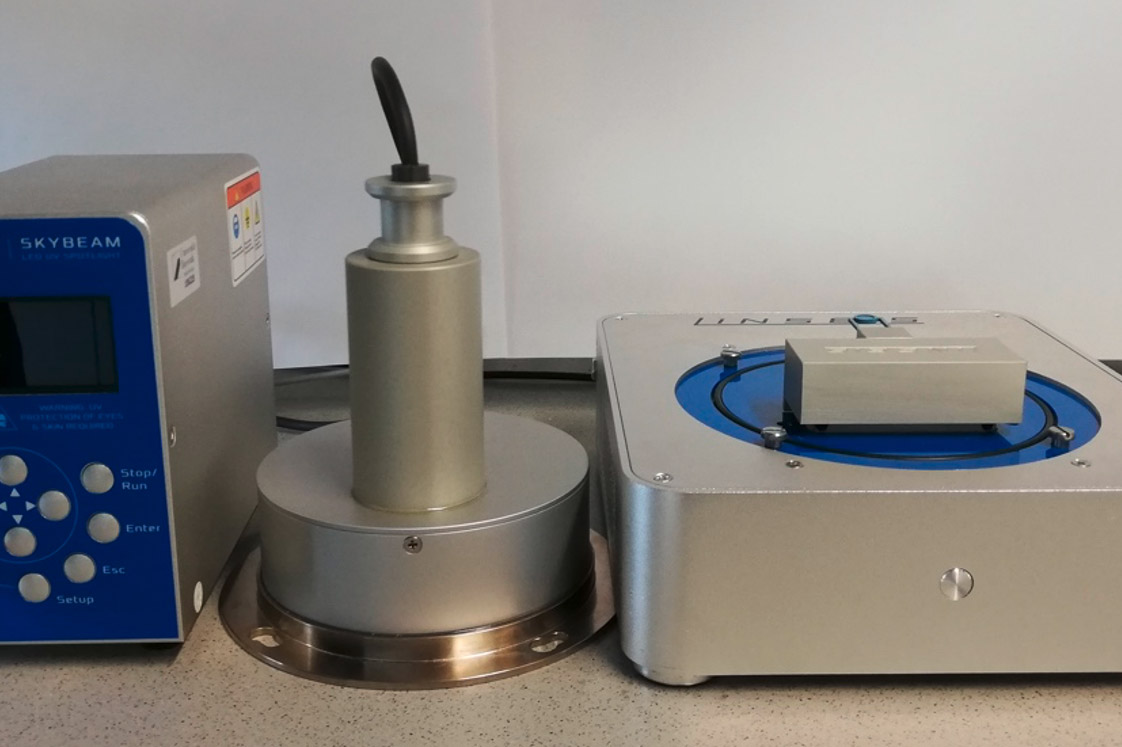

Temperature range [°C] 25 – 600 (+/- 0.2 )

Resolution [µW] 0.03

Measuring range [mW] +/- 2.5 – +/- 250

Heating rate [°C/min] 0.001 – 300

Cooling rate [°C/min] 0.001 – 300

UV LED lamps [nm] 365 and 405

UV irradiance (365 nm) [mW/cm^2] 20 – 4400

UV irradiance (405 nm) [mW/cm^2] 35 – 2100

Purge gas

Inert, (other gases possible)

Chip sensor

All the necessary parts of a DSC installed (oven, sensor, and electronics).

Software

Chip DSC and Linseis TA evaluation

Location: University of Bayreuth

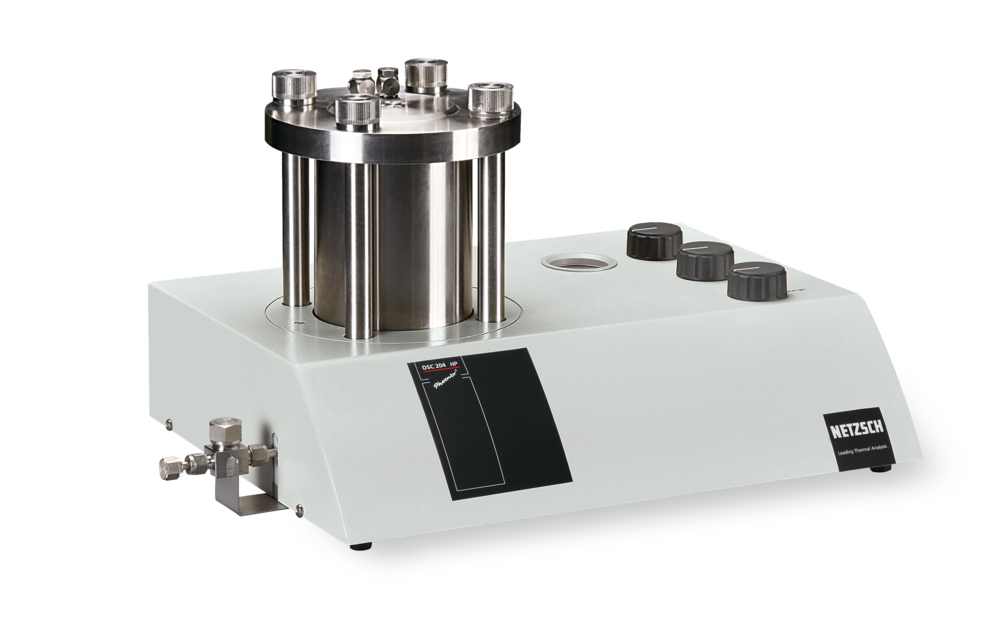

Pressure range [MPa] vacuum up to 15 (150 bar)

Pressure accuracy

0%

Temperature range (depending on gas type) [°C] – 150 – 600 (at 1 bar), 90 – 600 (at 50 bar), 50 – 450 (at 150 bar)

Heating rates [K/min] 0.01 – 100

Cooling rates [K/min] 0.01 – 50

Purge gas flow [ml/min] up to 500

Test gas

Nitrogen, carbon dioxide (other gases possible on request)

Software

Proteus®

Location: University of Bayreuth

Standort: Universität Bayreuth

The DEA allows viscosity tracking and determination of the degree of cure for thermosetting resin systems, adhesives, paints, and fibre composites, both in a laboratory environment and under real industrial conditions.

Thermal and UV-induced curing systems can be investigated.

Frequency [Hz] 1 mHz- 1 MHz

Temperature range [°C] RT to 275

Data points [ms] possible < 5

Curing mechanism thermal, UV

Location: University of Bayreuth

Wavelength [cm-1] 400 – 4000

Wavenumber Precision [cm-1] better than 0.0008

Optical resolution [cm-1] Less than 0.09

Beam splitter

KBr

Laser

HeNe

Accessories

- ATR-Module

- Heating stage up to 200 °C

- TGA Interface

- Measurements in Transmission

Software

Omnic Software with comprehensive database

Location: University of Bayreuth

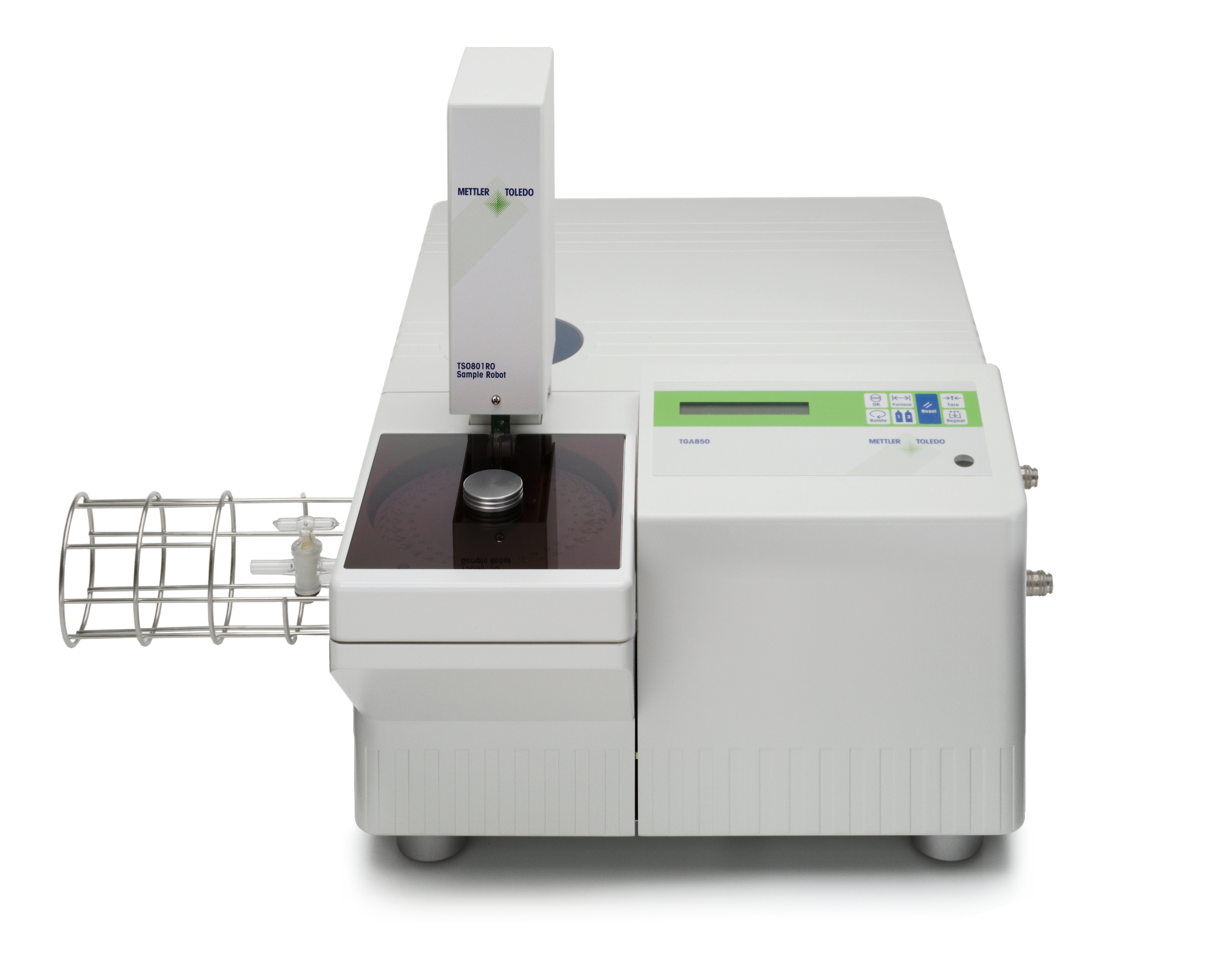

Temperature range [°C] 25 – 1100 (+/- 0.25 %)

Weighing range [g] 5 (MT5)

Resolution [µg] 1

Signal time constant [s] 15

Sample volume [μl] up to 900

Purge gas

Nitrogen, oxygen, air

SDTA sensor

FRS1 R-Typ (Pt-Pt-Rh 13 %)

Features

- Horizontal furnace construction with gas-tight measuring cell

- Coupling with FTIR

Software

STARe

Location: University of Bayreuth

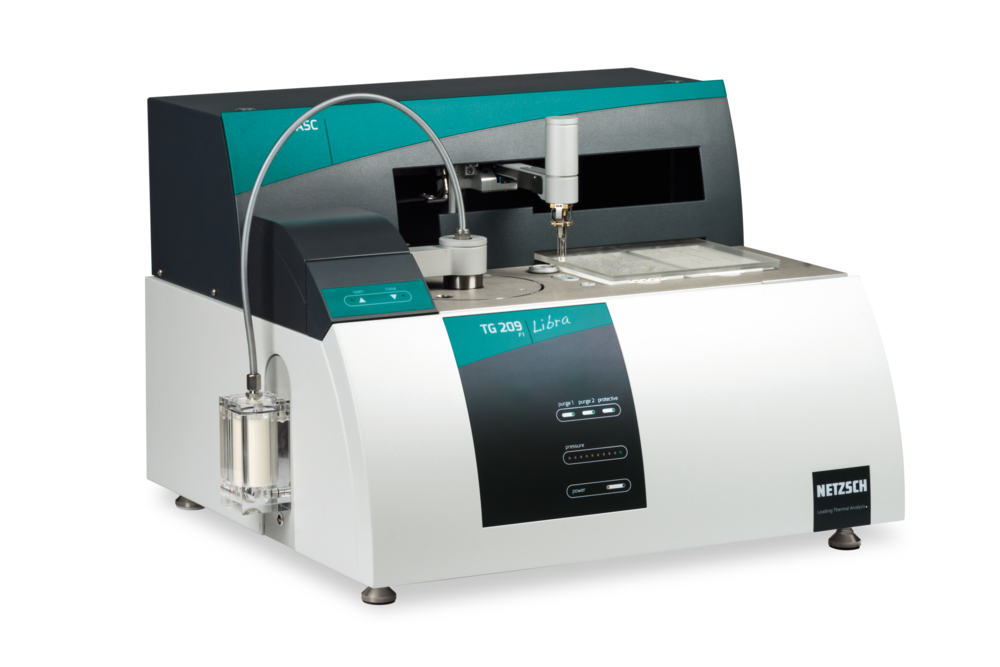

Temperature range [°C] 25 – 1100

Heating rates [K/min] 0.001 – 200

Weighing range [mg] 2000 (MT5)

Resolution [µg] 0.1

Sample volume [μl] up to 85

Temperature calibration

c-DTA®, direct measurement of sample temperature, Curie Standards

Purge gas

Nitrogen, oxygen, air

Features

- Sample changer for 180 samples

- AutoVac (automatic evacuation and filling with purge gas)

- Vacuum-tight down to 10-2 mbar (1 Pa)

- BeFlat® function (automatic correction of the baseline)

Software

Proteus®

Location: University of Bayreuth

Thermomechanical analysis (TMA) determines dimensional changes of solids, liquids, or pasty materials under defined mechanical load as a function of temperature and/or time.

Temperature range [°C] -70 … 400

Maximum sample dimensions [mm] 26 x 10 mm (cube), 26 x 1 x 4.7 mm (fibre, static), 26 x 0.35 x 4.7 mm (fibre, dynamic)

Measuring accuracy [%] 0.1

Temperature accuracy [°C] 1

Measuring resolution [nm] 15

Force range [N] 0.001 … 2

Frequency [Hz] 0.01 … 2

Measurement options

- thermal expansion

- creep

- stress relaxation

- storage, loss modulus

- air, inert gas, reactive gas

Software

Advantage Software

Location: University of Bayreuth

The HFM 446 small from Netzsch works according to the stationary heat flow method. Very small heat flow sensors are installed here so that the measuring geometry can be variably adapted to the installation space.

Measuring range [W/mK] 0.007 – 2

Accuracy [%] ± 1 to 2

Repeatability [%] ± 0,25

Temperature range [°C] 0 – 90 (mean temperature)

Sample size [mm2] 5 x 5 (minimum)

Sample size [mm2] 200 x 200 (maximum)

Sample thickness [mm] 1 – 50 (automatic thickness determination)

Software

Proteus 85 (Smart mode)

Location: University of Bayreuth

The FOX50 from Lasercomp works according to the stationary heat flow method. In addition to thermal conductivity, the thermal surface resistance of the sample can be determined using the two-thickness measuring method.

Measuring range [W/mK] 0.1 – 10

Precision [%] 3

Temperature range [°C] 18 – 100 (+/- 0.02) (average temperature)

Sample size [mm] Ø 60

Sample thickness [mm] 1 – 25 (+/- 0.025)

Software

WinTherm 50

Location: University of Bayreuth

The THB 100 works according to the “heating bridge method”, which belongs to the class of transient methods for measuring the thermal transport properties of substances.

In contrast to the steady-state methods, thermal diffusivity can be determined at the same time as thermal conductivity.

Thermal conductivity [W/mK] 0.02 – 30 (+/- 3%)

Thermal diffusivity [mm2/s] 0.05 – 10 mm2/s (+/- 5%)

Temperature [°C] 25 – 200

Minimum sample size [mm] 4 x 4 x 4

Maximum sample size unlimited

Sensor type

Insulated capton sensor (40 x 20 mm), Hot – Point – Sensor (4×4 mm)

Software

Linseis Thermoanalyse

Location: University of Bayreuth