Sample preparation

Achieving reproducible measurement results from test samples

We have a wide range of appropriate equipment such as grinding, polishing, drilling, and milling machines and saws to achieve the desired surface quality, sample geometry, and dimensional accuracy.

The Zehntner ZAA 2300 made by Proceq is an universal thin film applicator. The bed is heated, and so higher viscosity system can be handled.

Films can be made up to the length of 400 mm and 300 mm width.

Analog display

Length of the film: up to 400 mm

Width of the film: up to 300 mm

Temperature of the heated bed: 150 °C

Drawing speed: ZAA2300 1 mm/s – 90 mm/s

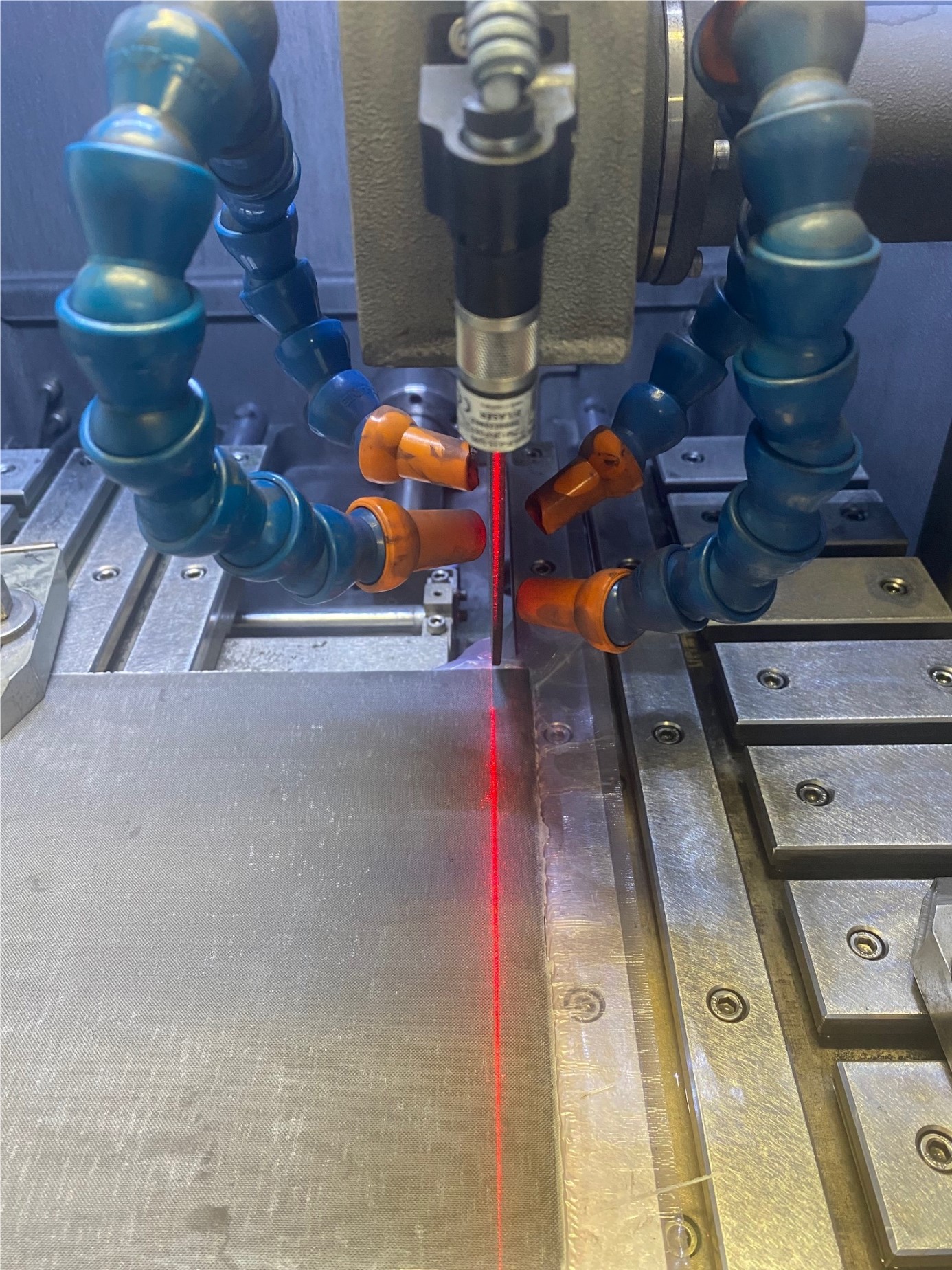

– Metkon SERVOCUT 402-AA-AX Wet Chamber Cutting Machine

– Disk diameter 400 m

– Automatic cutting

– 600-2400 rpm

– Table speed 1 µm/s – 3 mm /s

– Laser positioning & Quick Clip

– Table dimension width:

o Z-axis 255 mm

o X-axis 150 mm

o Y-axis 300 mm

For punching out samples from soft (non-rigid) materials by means of punching knives (steel) and a pneumatic punching system in accordance with international standards (ISO, ASTM and other equivalents) and customer-specific requirements.

Location: University of Bayreuth

Contact: M. Sc. Florian Schönl

Phone: +49 921 55 7512

E-mail: florian.schoenl@uni-bayreuth.de

The CNC sample saw is suitable for the semi-automatic production of shoulder bars and other specimens according to DIN, ISO, ASTM, or special dimensions in smaller quantities. A wide range of geometries can be realised via its Edi-Tasc 3D control. A spray rinsing device ensures uniform cooling of the workpieces and thus perfect cut edges.

Speed range [1/min] 2,000 to 16,000

Motor output [W] 250

Collet chuck diameter [mm] 0.5 to 4

Working range [mm] x-axis approx. 560, y-axis approx. 270, z-axis approx. 60

Drilling / workpiece height [mm] 60 / 180

Milling capacity [mm] aluminium up to 2, plastics up to 4

Features

Spray mist and suction device

Software

Edi-Tasc 3D

Location: University of Bayreuth

Maximum force [kN] 130

Maximum surface load [MPa] 80

Maximum temperature [°C] 500

Maximum piston stroke [mm] 50

Hotplate dimensions [mm] 160 x 160

Location: University of Bayreuth

The Diadisc circular saw is used for a variety of machining tasks. It is used both for pre-machining samples before the subsequent milling or grinding process, and for producing notched samples for the notch impact test. A spray mist device ensures optimum cooling of the materials.

saw blade diameter [mm] 125

Features

- diamond saw blades

- solid carbide saw blades with various teeth

- V-groove saw blade (for CT specimens)

- V-groove saw blade (for notched bar impact specimens)

- spray mist device

- suction device

- motorised table feed

Location: University of Bayreuth

Features

Automatic timer, pressure variation

Location: University of Bayreuth

The Variable Speed Rotor Mill PULVERISETTE 14 is used for the preparation of temperature-sensitive samples. These can be comminuted, as the thermal load on the material to be ground is reduced by fast, effective grinding. Samples that are difficult to grind, such as styrenes, polyesters, synthetic resins, films, PVC, PP, and PE, can be embrittled, e.g. by adding liquid nitrogen, and then ground to analytical fineness.

A very fast-running rotor with moulded ribs comminutes the sample by impact. In addition, sharp-edged teeth together with the inserted sieve cut the sample by shearing. In the final comminution stage, the sample is stressed by friction between the rotor and sieve.

Regulated rotor speed [U/min] 6.000-20.000

Frequency [Hz] 50-60

Absorbed power [W] 1150

Sieve insert [mm] 0,5; 1,0; 2,0

Grinding tool

Lock rotor

Location: University of Bayreuth

The unit with its working area of 1,300 x 1,300 mm² is mainly used for the preparation of samples from a wide range of materials.

Since FLOW MACH2 has a maximum cutting jet pressure of 3,800 bar, and the use of abrasive materials is possible, almost all materials – from plastic foam to high-strength steel – can be cut. In addition, the system has an engraving function that enables direct specimen marking. The integrated “UltraPierce” piercing aid prevents the cutting jet from running off at the starting point of the cutting line. This leads to perfect cutting results accurate to +/- 0.1 mm/m and a reproducibility of 0.8 mm, especially when machining fibre composite components.

Contact: Robin Fachtan

Phone: +49 921 507 36 210

E-mail: robin.fachtan@nmbgmbh.de

Property of Neue Materialien Bayreuth GmbH

Location: Neue Materialien Bayreuth GmbH