Additive Manufacturing

Tailor-made Materials for new Applications

Complex geometries, individualized components, flexible and fast development processes – additive manufacturing promises these and many other advantages. However, in order to fully develop its potential, the young technology still has to tackle many challenges. It is important to perceive additive manufacturing not only as a replacement for known technologies, but to use its strengths to generate added value. Therefore three aspects are essential for us: an optimal interplay of material and process, the intelligent use of the digital environment and the focus on applications where advantages such as individualization or functionalization can be fully exploited.

Another core competence of our target-oriented research is the implementation of the entire process chain from raw material to processing to the final component. Currently, our focus is on thermoplastic-based fused filament fabrication (FFF) and thermoset-based digital light processing (DLP). Neue Materialien Bayreuth GmbH also offers access to other additive manufacturing technologies https://www.nmbgmbh.de/verfahren/additive-fertigung/.

Contact: Niklas Bauriedel, M. Sc.

Phone: +49 921 55 7481

Mail: niklas.bauriedel@uni-bayreuth.de

Build volume [mm] 256 x 256 x 256

Maximum nozzle temperature [° C] 320

Maximum printing bed temperature [° C] 110

Maximum printing chamber temperature [° C] 60

Technology

Fused Filament Fabrication (FFF)

Materials suited

Diameter 1.75 mm, open filament system, filled and unfilled filaments

Printing system and specials

- High speed FFF printer up to 500 mm/s

- Automatic multimaterial system (AMS) with up to 4 materials

- Direct drive extruder system

- LiDAR Sensor and AI tools for optimized printing quality

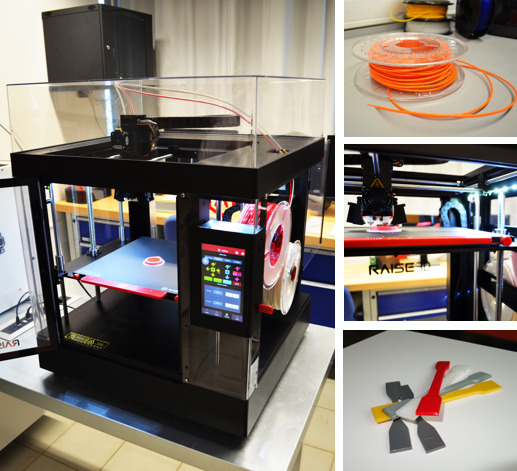

Build volume [mm] 305 x 203 x 300

Maximum nozzle temperature [° C] 300

Maximum printing bed temperature [° C] 110

Technology

Fused Filament Fabrication (FFF)

Materials suited

Diameter 1.75 mm, open filament system, filled and unfilled filaments

Print system and specials

- Print head for dual extrusion with exchangeable nozzles

- Direct drive extruder

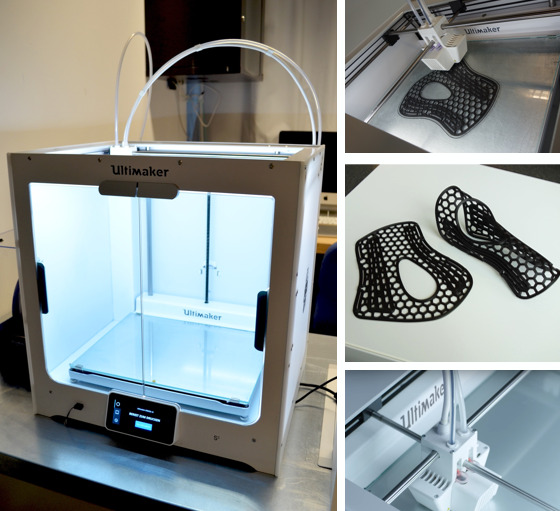

Build volume [mm] 230 x 240 x 300

Maximum nozzle temperature [° C] 280

Maximum printing bed temperature [° C] 140

Technology

Fused Filament Fabrication (FFF)

Materials suited

Diameter 2.85 mm, open filament system, filled and unfilled filaments

Print system and specials

- Print head for dual extrusion with exchangeable nozzles

- Bowden extruder

- Automatic bed leveling

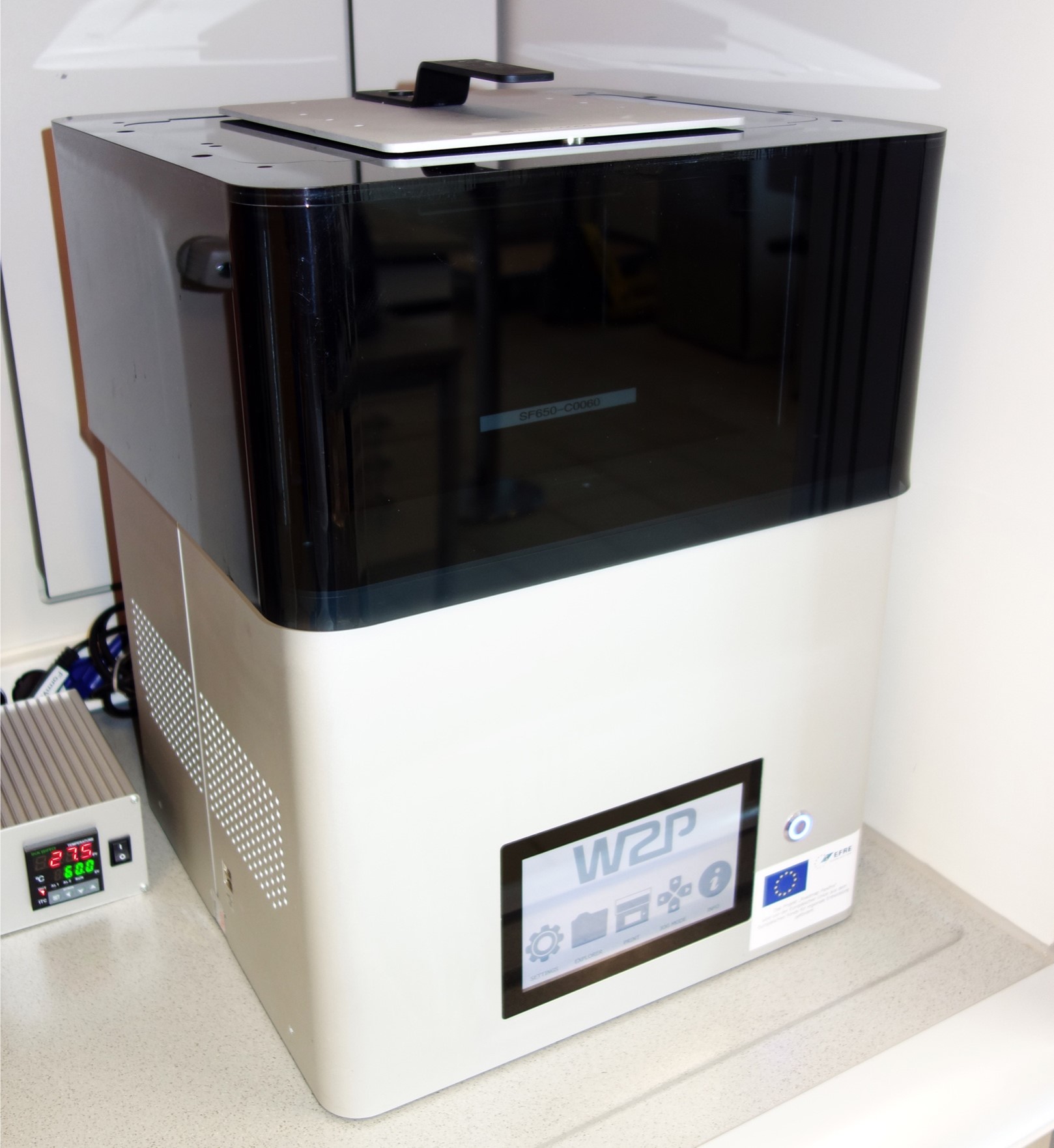

Maximum installation space [mm] 128 x 120 x 130

Layer thickness [µm] 25-200

Ambient temperature [° C] 18-28

Print speed [mm/h] 120

Technology

UV-LED DLP, 405 nm wavelength

Materials suited

W2P approved materials, UV-curable systems

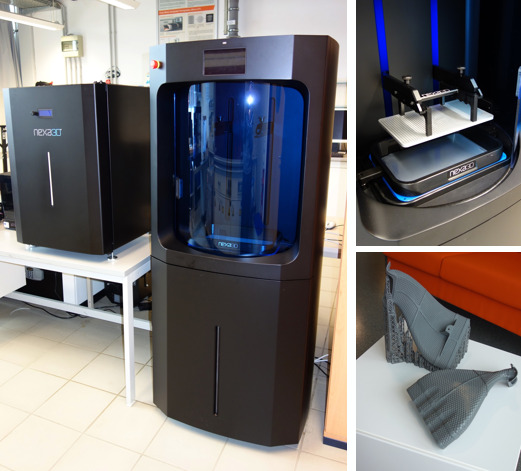

Maximum installation space [mm] 270 x 160 x 400

Layer thickness [µm] 500 / 100 / 200

Ambient temperature [° C] 18-28

Print speed [mm/h] up to 1cm/min

Technology

continious LSPc printer, 405 nm wavelength

Materials suited

open material system, UV-curable systems

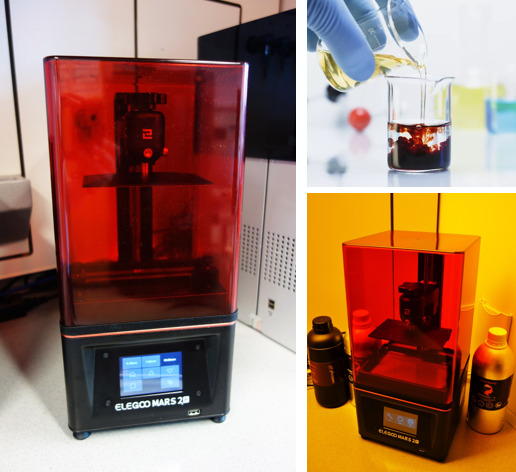

Maximum installation space [mm] 130 x 82 x 160

Layer thickness [µm] 10-200

Ambient temperature [° C] 18-28

Print speed [mm/h] 30-50mm/h

Technology

DLP printer with LED display, 405 nm wavelength

Materials suited

open material system